| Displacement cc/rev: | 25 - 152 |

| Gear Widths: | 1/2" - 3" |

| Max PSI / BAR: | 2250 / 155 |

| RPM: | 400 - 2000 |

P3700 Series

The P3700 series is a large displacement, roller bearing gear pump from Permco.

Free Technical Downloads

Product Overview

The Permco P3700 is a large frame sized, hydraulic roller bearing gear pump.

The P3700 series gear pump is built from cast iron ensuring a strong and long lasting product, which can stand the most robust applications. Single & multiple units are available as per your requirements.

With the double bearing design, the P3700 is suitable for the handling of heavy side and axial loads.

The pressure loaded wear plates of the pump, provides you with a high efficient product.

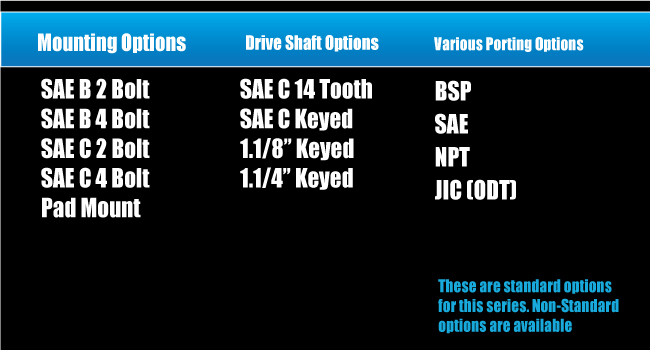

A wide range of configurable mounting, shaft and porting options are available to suit your unique requirements.

Compatible with Mineral Oil, Water Glycol, Invert Emulsion & Fire Resistant fluids.

Spare parts available from stock, such as seal kits, flanges, shafts and individual pump sections enabling a fast turnaround for you if required.

Our Service to you

We machine, build from stock and test the P3700 gear pump on site, to ensure the highest quality and a workable product is delivered to you. The P3700 gear pump also comes with a 12 month warranty.

We aim to always supply the best competitive price for this product. Your welcome to provide us with a guide price to see if we can price match it.

In the event your product breaks down in the first 12 months, please CONTACT US so we can discuss your warranty rights with you.

In the event of an emergency or you have a machine breakdown; we can supply this product to you with a 24 / 48 turnaround.

Common Applications

Customers of ours have used this gear pump in applications such as:

- Applications within the oil field

- Gas Turbines

But can be applied to a wide range of mobile machinery within a variety of industries.

ATEX Information

The P3700 can be supplied as an ATEX gear pump if required. ATEX Group I & II approval is required, if the product will be used in potentially explosive atmospheres.

ATEX gear pumps are ideally suited for applications in the mining, oil & gas industry.

Mounting, Drive Shaft, Porting Options

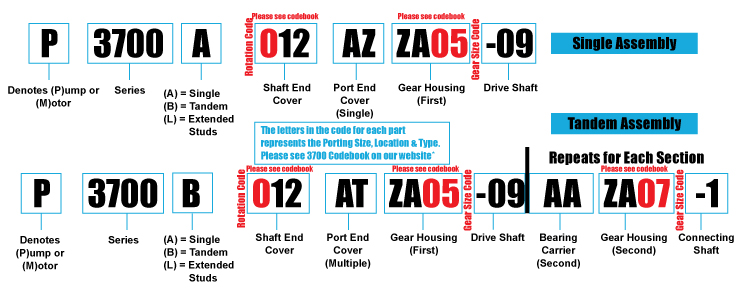

Product Coding Example

Pump Performance

Recommended Operating Conditions

- Fluid viscosity, normal operating conditions 16 – 220 cst.

- Fluid temperature should not exceed 65 deg C.

- Fluid cleanliness, 10 micron filter with Beta 200 rating is recommended.

- Inlet pressure; for best operation with mineral oil, pressure should not exceed minus 0.237 BAR (7 in HG).

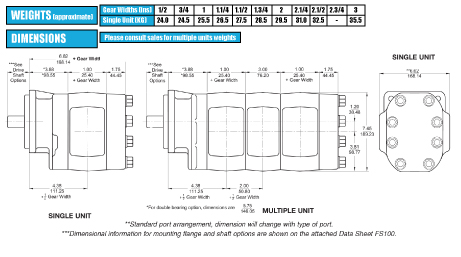

Weights & Dimensions